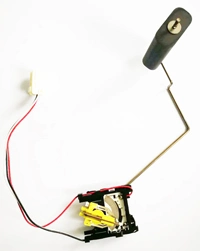

Fuel level sensor (FLS) introduction

FDS is working with the biggest FLS OEM manufacturer in China and specially focus on the after sales market, at present, we can supply Fuel level sensor of Bosch system, Continental system, Delphi system etc. The quality is same as the original part but cost is much cheaper.

Notes: FDS also can provide OEM service for the customer.

FLS assembly plant:

FDS is working with the biggest FLS OEM manufacturer in China and specially focus on the after sales market, at present, we can supply Fuel level sensor of Bosch system, Continental system, Delphi system etc. The quality is same as the original part but cost is much cheaper.

| Physical information | |||

| Profile | FLS assembly parts | Main material | Special treatment |

| Plastic holder | POM | |

| Thick film circuit | Al2O3 96% & PdAg ink | surface polishing | |

| Steel wire | Stainless steel | Nickel plating | |

| Float | NBR | ||

| Wiper body | POM | ||

| Spring contact | Beryllium bronze | ||

| Contact terminals | Au-Pd, Au-Ni | welding connection | |

| Harness | Tinned CU | ||

| Connector | POM | ||

| Technical informations | |||

| Operating temperature: | -45ºC~120ºC | ||

| Angles & Height | wiper movement angle 45° - 120°, or customized | ||

| Resistance value | Full tank to empty tank, 10ohm to 300ohm or customized | ||

| Wear resistance cycles | depends on the parts materials, Max 5,000,000 times cycles | ||

| Tolerance | Resistance: ±1% Ω, Fitment dimentions: ±0.1mm | ||

| Fuel resistance | The FLS can be work in gasoline of E10/E20/E30/M15, Diesel | ||

| Certification | IATF 16949: 2016 | ||

| Test standard: | Volksvagen AK-LH20.1 2007 | ||

FLS assembly plant: